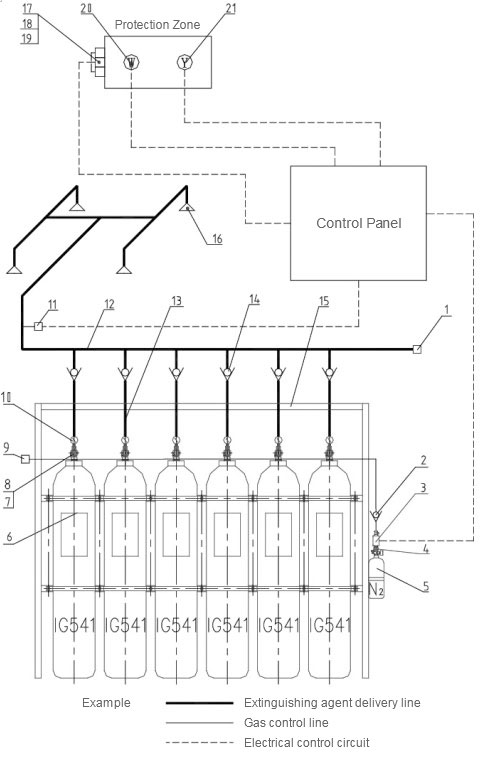

| 1.Safety discharge device | 2.Drive gas line one-way valve | 3.Drive device (electromagnetic type) |

| 4.Container valve (drive gas) | 5.Drive gas bottle group | 6.Extinguishing agent bottle group |

| 7.Container valve (Fire extinguishing agent) | 8.Pneumatic manual starter | 9.Low leakage high sealing valve |

| 10.Pressure gauge | 11.Signal feedback device | 12.Collecting pipe |

| 13.Connecting pipe | 14.Extinguisher circulation line one-way valve | 15.Bottle holder |

| 16.Nozzle | 17.Emergency Start/Stop Button | 18.Gas release door light |

| 19.Sound and light alarm | 20.Heat detector | 21.Smoke detector |

| 1.Safety discharge device | 2.Drive gas line one-way valve |

| 3.Drive device (electromagnetic type) | 4.Container valve (drive gas) |

| 5.Drive gas bottle group | 6.Extinguishing agent bottle group |

| 7.Container valve (Fire extinguishing agent) | 8.Pneumatic manual starter |

| 9.Low leakage high sealing valve | 10.Pressure gauge |

| 11.Signal feedback device | 12.Collecting pipe |

| 13.Connecting pipe | 14.Extinguisher circulation line one-way valve |

| 15.Bottle holder | 16.Nozzle |

| 17.Emergency Start/Stop Button | 18.Gas release door light |

| 19.Sound and light alarm | 20.Heat detector |

| 21.Smoke detector |

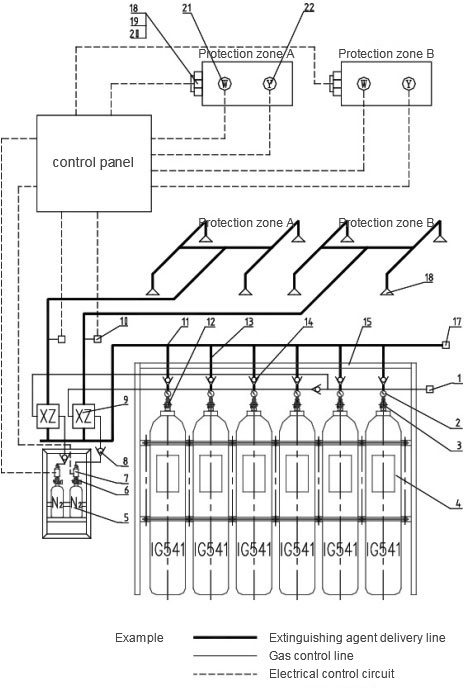

| 1.Low leakage high sealing valve (Drive gas) | 2.Pressure gauge | 3.Container valve (Fire extinguishing agent) |

| 4.Extinguishing agent bottle group | 5.Drive gas bottle group | 6.Container valve (drive gas) |

| 7.Drive device (electromagnetic type) | 8.Drive gas line one-way valve | 9.Select valve |

| 10.Signal feedback device | 11.Collecting pipe | 12.Pneumatic manual starter |

| 13.Connecting pipe | 14.Extinguisher circulation line one-way valve | 15.Bottle holder |

| 16.Nozzle | 17.Safety discharge device | 18.Emergency Start/Stop Button |

| 19.Gas release door light | 20.Sound and light alarm | 21.Heat detector |

| 22.Smoke detector |

| 1.Low leakage high sealing valve (Drive gas) | 2.Pressure gauge |

| 3.Container valve (Fire extinguishing agent) | 4.Extinguishing agent bottle group |

| 5.Drive gas bottle group | 6.Container valve (drive gas) |

| 7.Drive device (electromagnetic type) | 8.Drive gas line one-way valve |

| 9.Select valve | 10.Signal feedback device |

| 11.Collecting pipe | 12.Pneumatic manual starter |

| 13.Connecting pipe | 14.Extinguisher circulation line one-way valve |

| 15.Bottle holder | 16.Nozzle |

| 17.Safety discharge device | 18.Emergency Start/Stop Button |

| 19.Gas release door light | 20.Sound and light alarm |

| 21.Heat detector | 22.Smoke detector |

| System implementation standards | GA400-2002 "Gas Extinguishing Systems and Components Performance Requirements and Test Methods" |

|

| Ambient temperature (℃) | 0~50 | |

| Pressure | Storage pressure (at 21°C) MPa | 15.0 |

| Maximum working pressure (at 50°C) MPa | 17.2 | |

| Minimum working pressure (0°C) MPa | 13.6 | |

| Storage container filling pressure (at 20°C) MPa | 15.0±0.2 | |

| System injection time (s) | ≤60s | |

| Delay time(s) | 0~30 | |

| Pipeline system maximum working pressure (MPa) | 7 | |

| Extinguishing agent bottle volume (L) | 80 | |

| Fire extinguishing agent filling rate (15MPa) | 211.15Kg/m³ | |

| Steel bottle external diameter (mm) |

¢279 | |

| Steel bottle height (mm) |

1640 | |

| Extinguishing agent filling capacity (latm, 20°C) Kg | 17 | |

| System operating voltage | AC220V 50Hz and DC24 V±15% | |

| Starting power supply | DC24 V 1.2A | |

| Drive gas bottle filling pressure (at 20°C) MPa | 6+0.3 | |

| Start gas medium | Nitrogen (N2) | |

| Protection area/volume | ≤800m2/3600m³ | |

| System startup mode | Electric automatic, electric manual, Pneumatic manual start, mechanical emergency operation | |

| Maximum flow from | Convert by the ratio of the volume of the pipe network to the total volume of the system bottle group which is less than 66% | |

COPYRIGHT © 2018 Wuxi Brightsky Electronic Co.,Ltd. ALL RIGHT RESERVED.

ICP 11076333-1